Light Hydroforming

weniger als 10% der Umformkraft gegenüber Hydroforming

HEAT formingTM benötigt weniger als 10% der Umformkraft gegenüber dem Hydroforming Prozess (IHU), dadurch sinken die Kosten für Anlagen, Werkzeuge und deren Betrieb sowie den Platzbedarf.

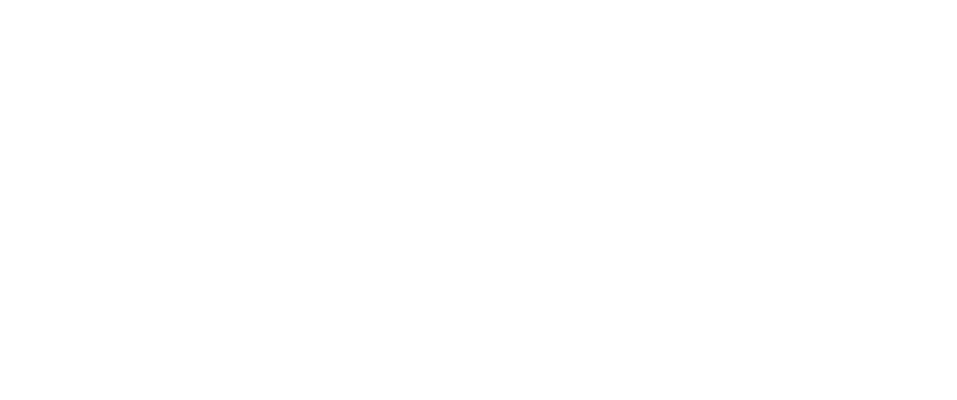

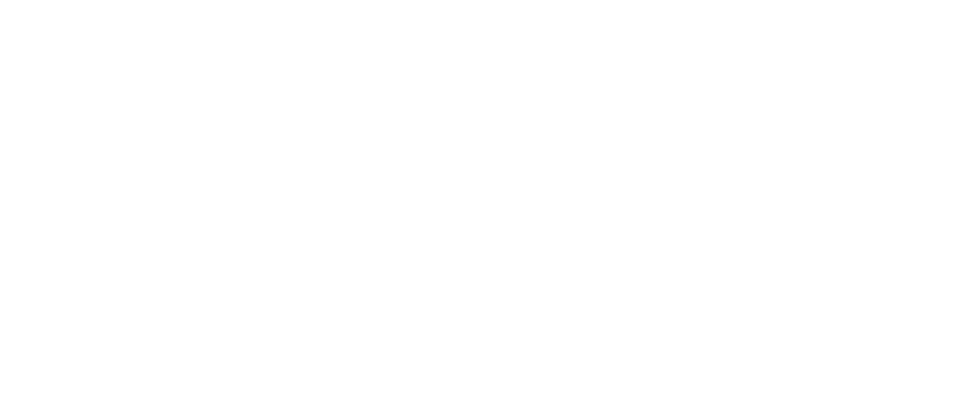

Dabei werden die bestehenden Grenzen in der Umformung drastisch verschoben, so dass komplexere Bauteile in nur einem Hub realisiert werden können. Der erzielbare Umformdruck ist nicht mehr ein limitierender Faktor. Hingegen ermöglicht HEAT formingTM die Konzentration auf die Bauteilauslegung und Optimierung des Einsatzgewichtes und damit auch der Einsparung immer wertvoller werdender Ressourcen.

Bauteilübersicht