Advantages

HEATform leads the industry in application of warm forming or Hot Metal Gas Forming (HMGF) for hollow bodies.

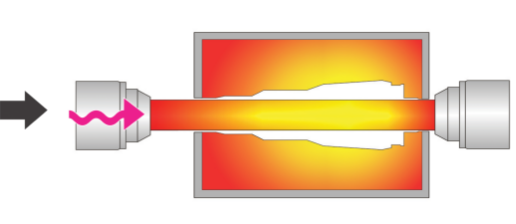

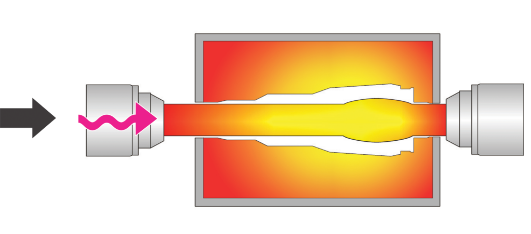

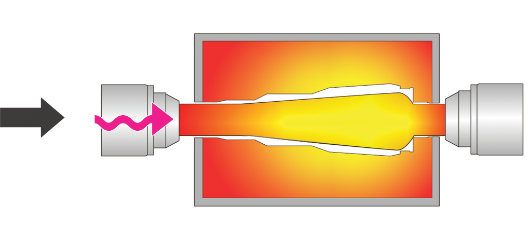

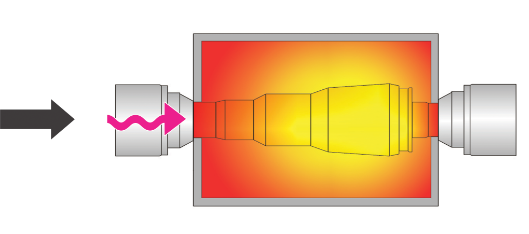

HEATform has developed and patented a unique forming technology. HEATforming uses inner gas pressure to form hollow bodies or tubes in almost all metals or alloys using temperature control to greatly enhance formability. Even alloys that do not form well at standard temperatures and high strength steel can be formed. Our process provides new freedom to engineers for product design and lightweight engineering.

An alternative to Hydroforming or SPF

HEATforming provides a competitive alternative to Hydroforming or Superplastic Forming (SPF) of tubes, and even die casting and forging in some cases.

Hot Metal Gas Forming (HMGF)

Hot metal gas forming (HMGF) - compare "HMGF" at wikipedia.org - , gasforming, warm forming or hot forming is often used to describe this metal forming process and is suitable for almost all tube blanks - extruded, drawn or seam welded.

In comparison to Hydroforming

Compared to Hydroforming, HEATforming provides higher forming ratios in less cycle time and in one process step. The HEATforming Equipment is much smaller, movable and can be easiliy integrated in a production line.