Various geometries of blanks

Various geometries of blanks

(Application: Cell elements for high performance)

Impact extruded blank and final Housing component with radial deformation

Impact extruded blank and final Housing component with radial deformation

(Application: Angle and Position measurement system, Level indicators )

Impact extruded blank and final Damper body with integrated ring mount flange

Impact extruded blank and final Damper body with integrated ring mount flange

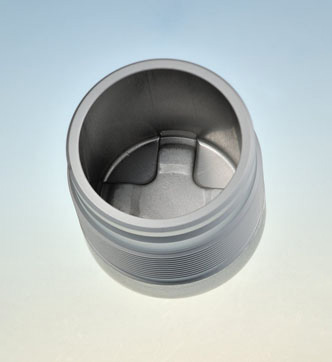

(Application: Front Screw cap for Power Steering assembly with integrated hex drive)

Impact extruded blank and final anodized part

HEATforming and impact extruded blanks represent a perfect combination for flexible, high quality, near net-shape manufacturing. In addition to creating accurate and cost effective open ended tubes, impact extrusions can be created with one end closed. The closed end can be formed with varying shape and material distribution to provide special attachment functions or increased strength. Another advantage of impact extruded blanks is the uniformity and control of wall thickness distribution. The wall thickness can be altered in specific areas of the blank, which is difficult in standard extruded tubes.

Impact extruded blanks can be produced in many aluminum alloys to meet various requirements such as strength, surface treatment suitability and corrosion resistance. Impact extruded blanks are well suited for use with HEATform techniques, and show a very fine grain after the hot forming process. This results in excellent surface finish after fine sanding and anodizing for decorative or functional applications. The combination of HEATform and Impact extrusion technology optimizes the use of raw material resulting in lighter, more economical components and assemblies. The process combination also leads to more consistent part geometry and mechanical properties. HEATform is collaborating closely with the impact extrusion specialist alutec.