Practical Superplastic Forming

HEATform gives you the possibility of superplasically forming materials by using a standard industrial manufacturing process.

Practical Superplastic Forming (SPF) requires exotic alloys, exacting temperature control, and slow, controlled, material flow.

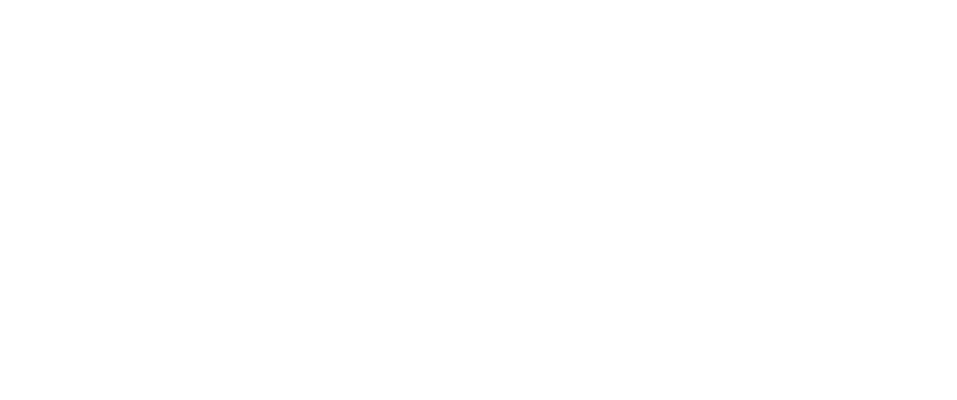

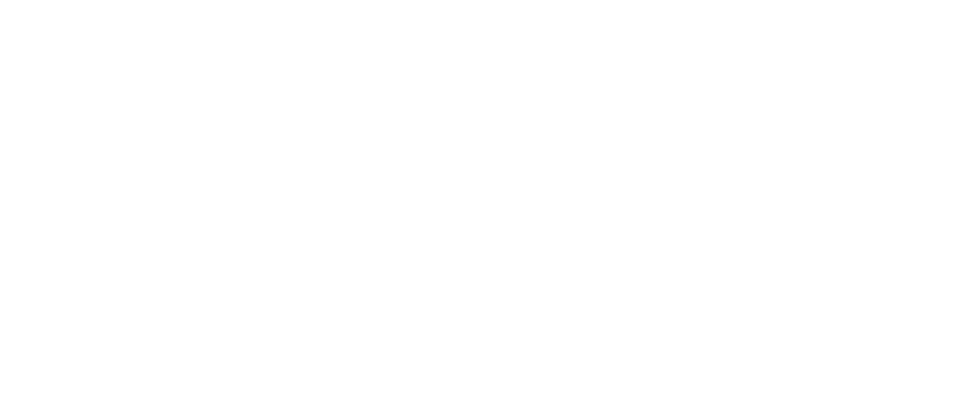

HEATform provides the forming freedom of super plastic forming with a standard, rapid manufacturing process. Exotic product designs, once exclusive to cost insensitive military applications, are available to all industry segments.

Markets